Introduction

When an unexpected promo surge strains Midwest operations with forecasting overshoot, logistics bottlenecks, and perilously low inventory a Sentienta Supply Chain team can help strategize solutions. In this post, we walk you through real-time data snapshots and individual agent analyses to show how distributed cognition transforms isolated insights into a unified, adaptive strategy that resolves complex fulfillment challenges.

The Supply Chain team consists of three specialized agents who think like experts and collaborate like a team.

- Miles: the Demand Forecaster, identifies unexpected sales surges and recalibrates forecasts to match emergent buying patterns.

- Isla: the Inventory Optimization Strategist, spots stockout risks and reshuffles resources across distribution centers to sustain availability.

- Talia: the Logistics Flow Strategist, detects fulfillment bottlenecks and reroutes shipments to maintain throughput and cost-efficiency.

Each agent works from their own specialized dashboard—focused on demand, inventory, or logistics—to identify emerging risks. Once surfaced, these distinct insights are shared across the team, enabling a coordinated strategy that addresses the full scope of the disruption.

The Data

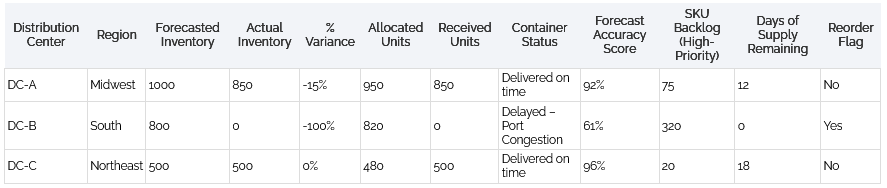

Isla’s Inventory Dashboard:

Key Insight: DC-B (South) shows a 100% inventory variance with zero actual inventory and delayed container status due to port congestion.

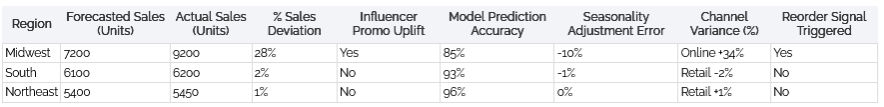

Miles’ Demand Dashboard:

Key Insight: Midwest region experienced a 28% sales spike driven by influencer uplift and online channel deviation—outpacing model expectations by a wide margin.

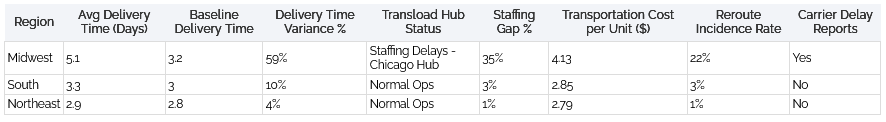

Talia’s Logistics Dashboard:

Key Insight: The Midwest region shows major logistics disruption: a 59% delivery delay, 35% staffing gap at the Chicago hub, and a $1.28 per-unit cost surge—triggered by reroutes and carrier delays.

Agent Insights – What the Dashboards Revealed to the Agents

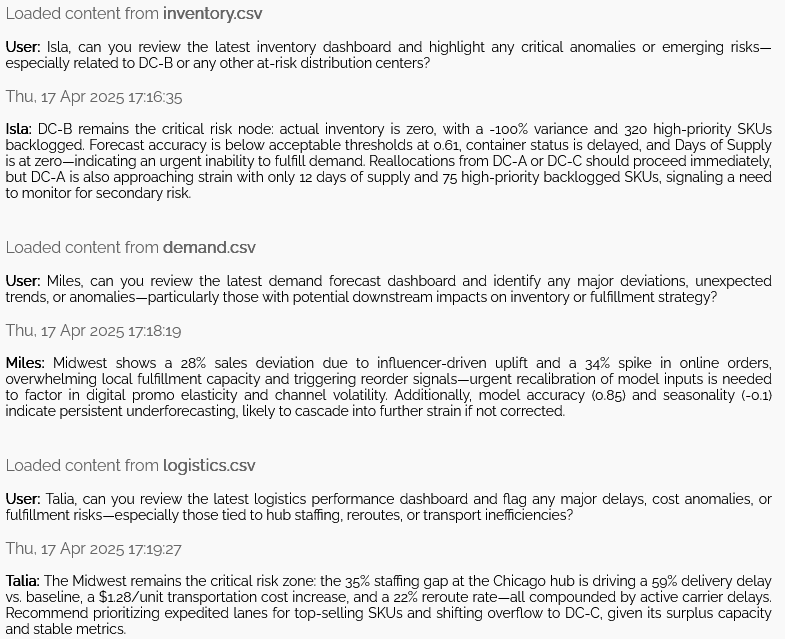

As part of the daily review cycle, each agent initiated a rapid diagnostic scan of their functional dashboards—surfacing anomalies, shortfalls, and emerging threats from the day’s incoming data load. The folllowing transcript captures the collaborative intake phase, where agent specialists flag critical issues in preparation for joint strategy formation. Their early assessments below form the baseline for downstream coordination.

Supply Chain Team Transcript: Agent Analysis

Orchestration and Strategy – When Agents Teams Work Together

After reviewing their functional dashboards, the Supply Chain agents transitioned from isolated diagnostics to integrated strategy formation. What follows is a transcript—condensed for clarity—that reveals how a distributed team of AI experts negotiated trade-offs, merged perspectives, and built a coordinated mitigation strategy for escalating Midwest risks.

Supply Chain Team Transcript: Team Analysis

The team co-developed a gated intake triage plan for DC-C with four synchronized filters: SKU velocity tier, forecast lock window, supply/demand thresholds, and margin-volatility pairing. They agreed to data handoffs via shared APIs and established cap tolerances to maintain flexibility under risk. This interaction exemplifies emergent cognition—where no individual agent held the entire solution, but collaboration yielded a coherent, executable plan.

Conclusion

This example highlights Sentienta’s core advantage: turning fragmented functional data into synchronized decision intelligence. As agents negotiate thresholds, define roles, and operationalize shared triggers, strategy becomes not just automated—but emergent. Sentienta Teams adapts at the pace of complexity, enabling businesses to respond with coordinated precision.